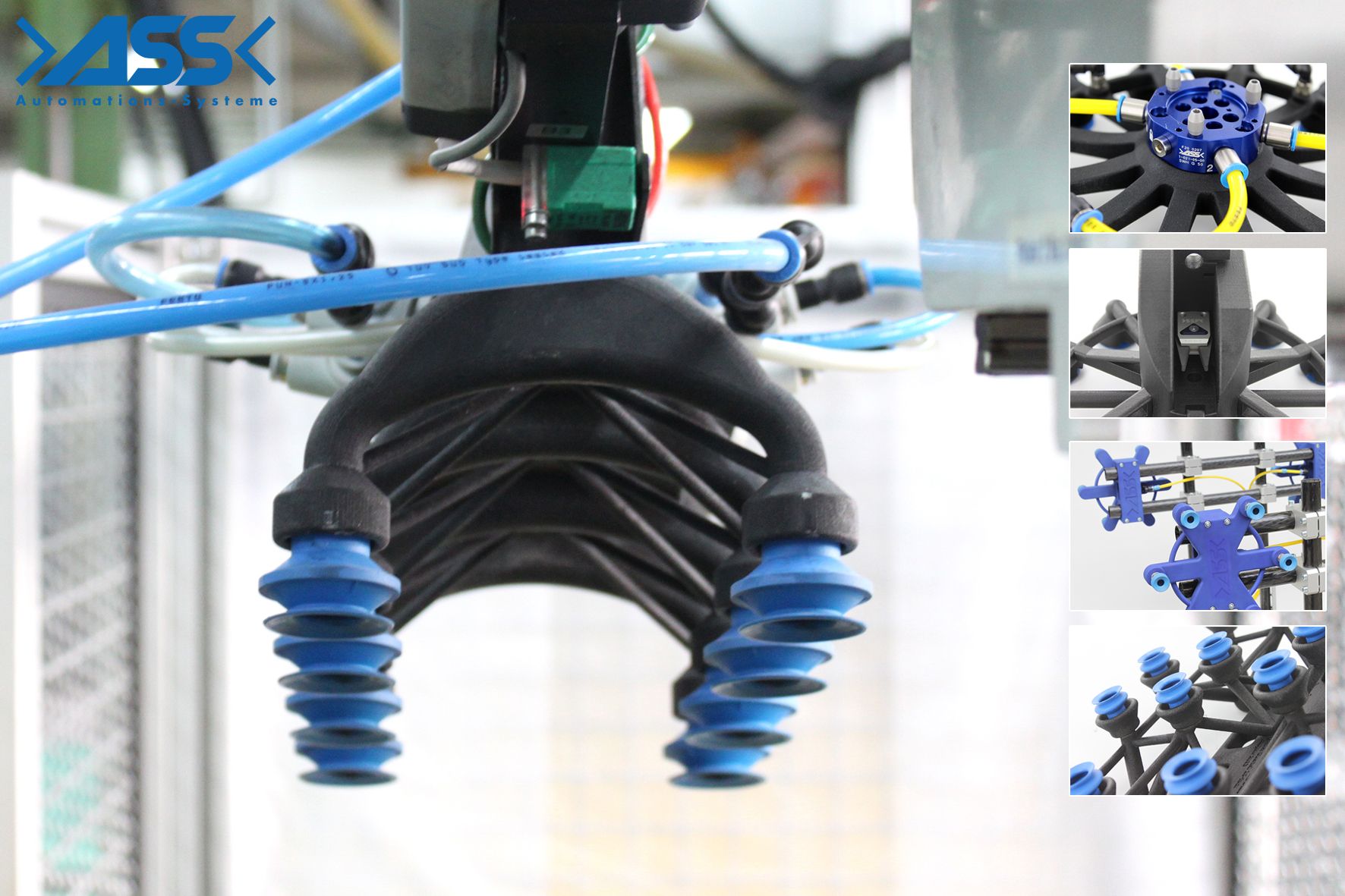

Lightweight gripper – combined with fingers

The lighter a gripper is built, the more energy-efficient it can be used.

"In order to be able to continue using the existing infrastructure and system technology at the customer's site, we combine our entire repertoire in a targeted manner for a simple and resource-saving handling solution. A reduced gripper weight also makes a decisive contribution when planning energy-efficient new systems. This fully corresponds to our consistent approach in terms of sustainability."

Wolfgang Breu, Business Development Manager at ASS Maschinenbau GmbH

When the load gets too big

A frequent customer requirement is the continued use of existing system technology in the form of robots or linear handling. When converting to new products, however, these often reach their handling weight limits. In addition, inquiries about energy-saving production solutions are no longer uncommon.

The sensible use of lightweight components often enables the customer to continue using the existing robots or to plan much smaller robot systems for their new systems.< /p>

Small systems with a big impact

To reduce weight, we combine and use additively manufactured components or, for ultra-lightweight construction, components made of carbon fiber reinforced plastic as a hybrid solution. We see the combination of these possibilities with our classic gripper system as the optimal solution, with consistent quality.

If the permissible handling weight of the handling comes up, for example a reduced working space or a complex component geometry, we often solve this with a completely additively manufactured gripper, which is a perfect addition to our portfolio. In order to save on peripherals, the air flow or functions are usually directly integrated into such a handling solution.

For very small and light components, we are also happy to use our award-winning Micro System as a complete and independent lightweight construction solution. A small system with a big effect! To do this, simply enter the search term "Micro" in the ASS online portal.

The best practice example from practice "Lightweight gripper maintains existing automation" is available for download: