Efficient manufacture of lightweight components for series production

The use of lightweight components and other flexible materials such as fibre-reinforced plastics (FRP) is becoming increasingly important in the automotive industry. A wide variety of limp materials often have to be moved reliably for this purpose, in addition to carbon fiber reinforced plastic parts (CFRP), including glass fiber reinforced plastics (GFRP), natural fibers over < strong>Carbon fiber fabrics to voluminous foams or the thinnest fine materials.

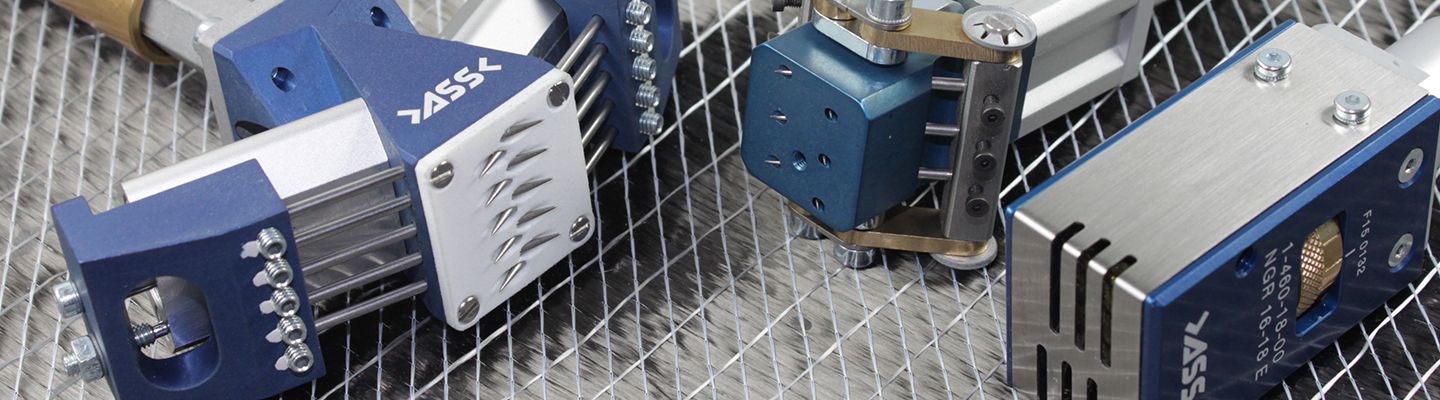

Lightweight components installed in automobiles reduce energy requirements by saving weight and increase safety through better rigidity and damping of the FRP products. In addition, the materials are more resistant to corrosion. As one of the most important tools for handling limp materials, we offer a range of needle grippers (NGR) in our catalogue, which are supplemented by numerous individually adapted versions:

Needle Gripper: Proven solutions - with great properties!

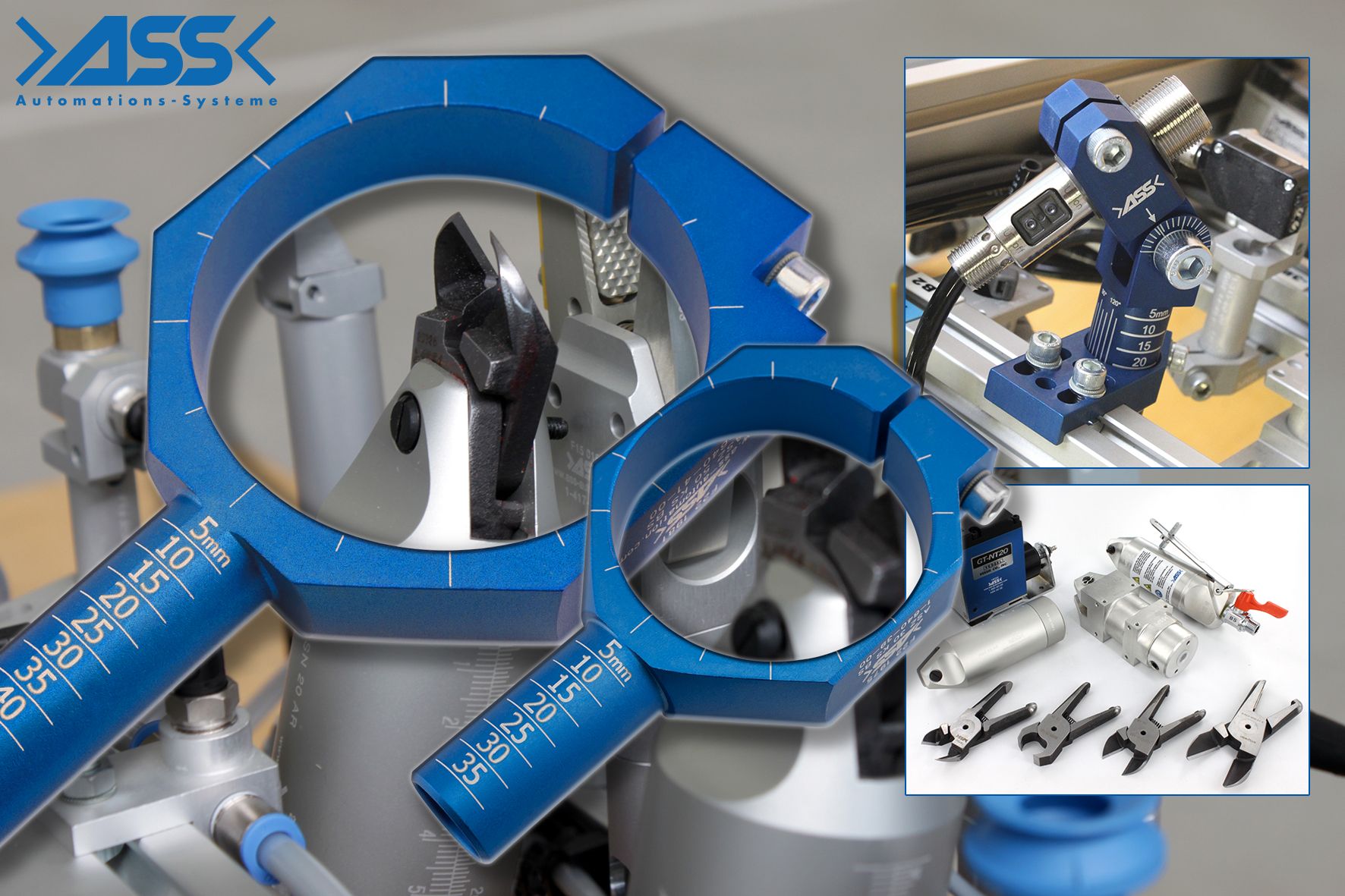

Small and precise piercing depths for safe gripping and lifting of stacks, inserting parts to be back-injected into the injection molding machine, picking up high-temperature masses and organo sheets, through to foam and felt mat handling with extra-long needles.

Regardless of whether functional insulation materials, sensitive interior materials or other materials are being handled:

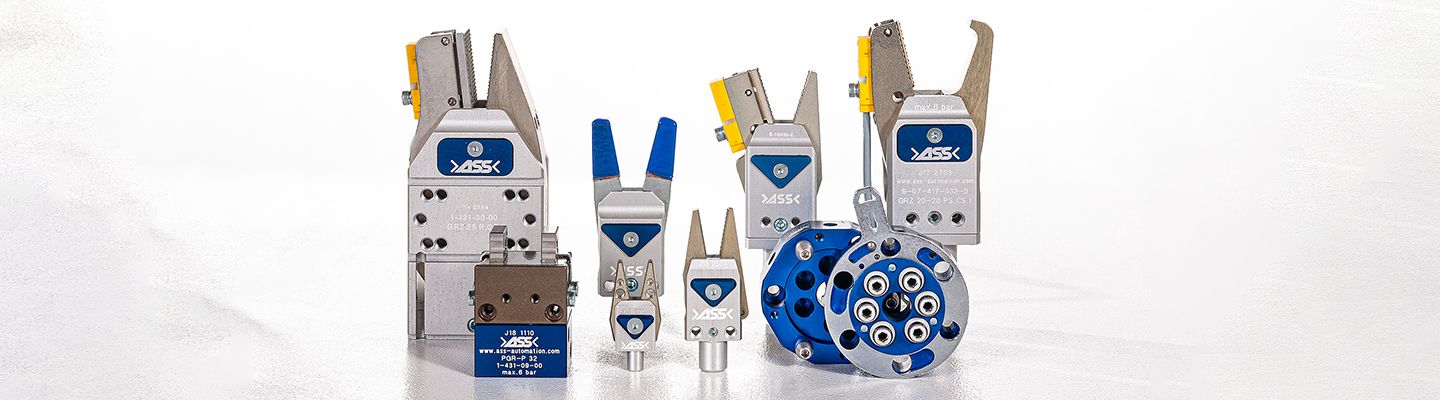

We at ASS Maschinenbau GmbH offer you the needle gripper that suits your requirements directly from stock or develop it in the shortest possible time time the tailor-made and process-reliable solution for you. You can always recognize needle grippers in our catalog by the abbreviation NGR. Some features of the needle grippers:

Methodical and solution-oriented approach

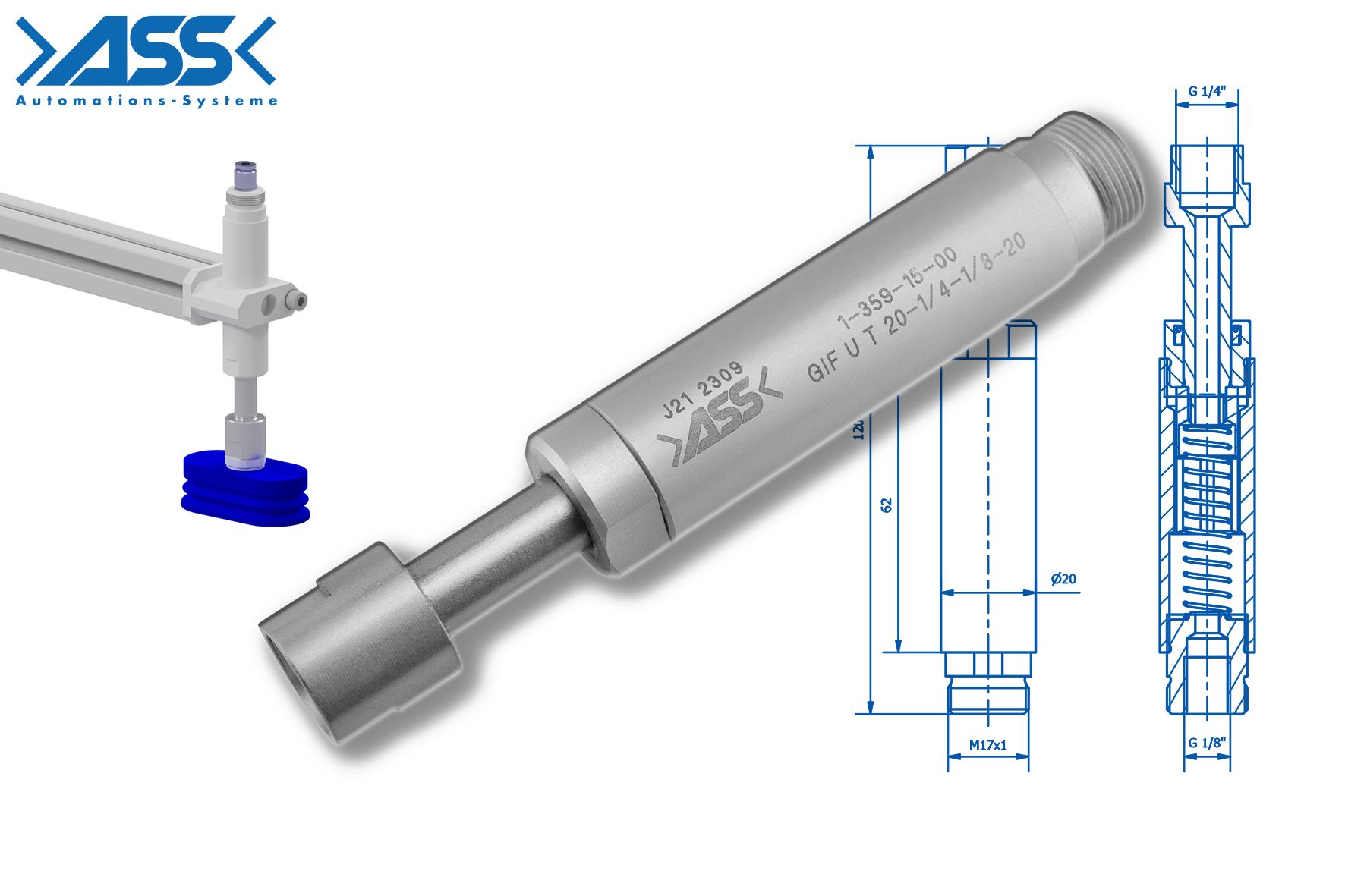

A needle gripper solution is available for every handling task. Flexible materials and components made of fiber composite or foam materials and textiles of all kinds can be handled reliably. The catalog portfolio therefore includes needle grippers with puncture depths from zero to over 80 millimeters and needle grippers with four to 36 needles. In addition, various special designs are available that are not included in the standard catalogue.

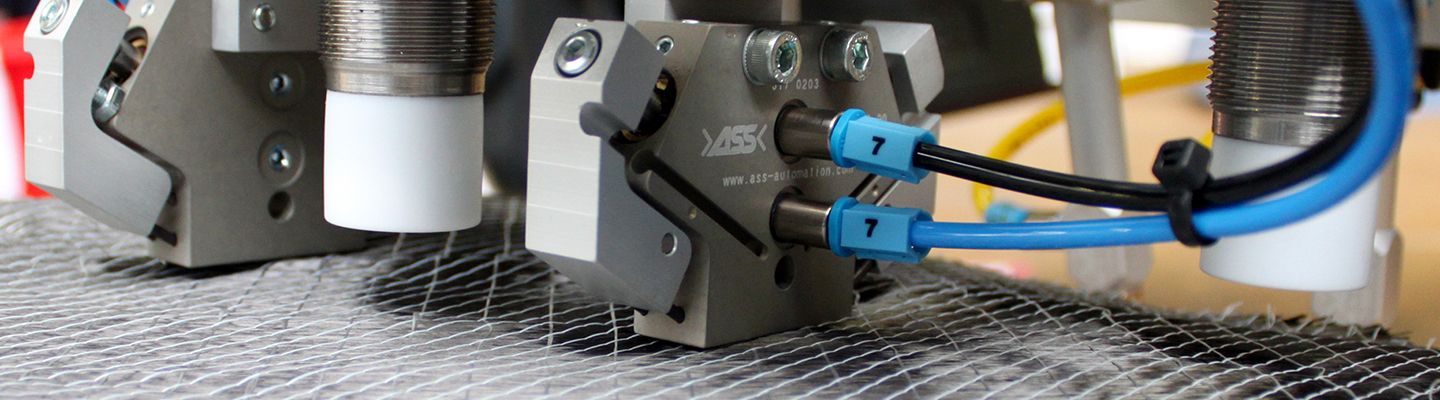

A position-accurate work is supported as required. For example, lockable centering units, centering bolts, gripper fingers and tongs, stack sensors and/or various sensors can be used for interrogation.

Heat-resistant components

During and after the heating of the material, it must be ensured that the material does not sag in the changed state of aggregation, retains the defined position and is deformed in the exact position.

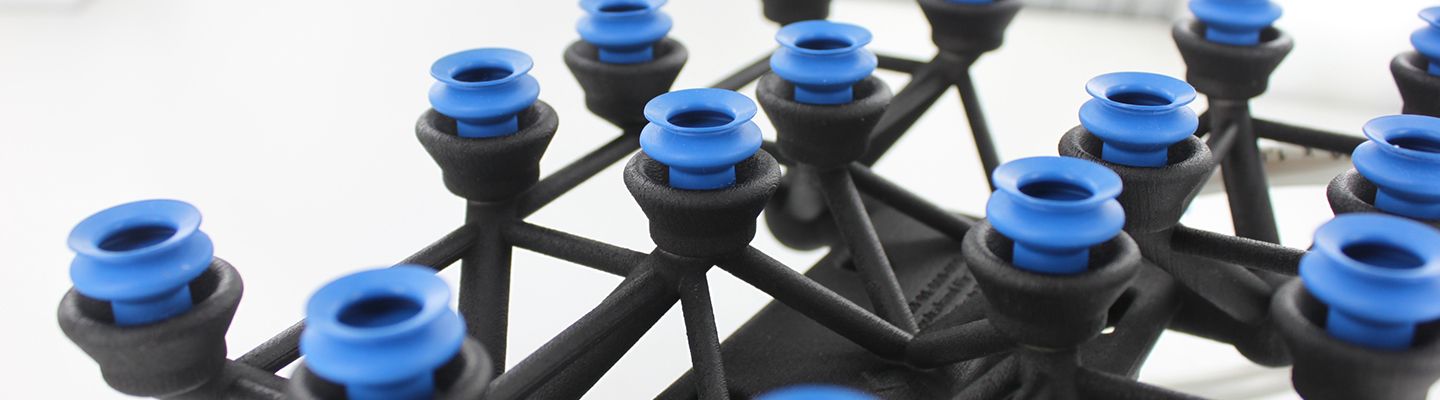

Needle grippers and insulators with heat-resistant properties that come into contact with components enable process-reliable handling of temperature-controlled materials. Even in heating fields, organic sheets or tough compound masses can be moved safely. Components such as heat-resistant vacuum cups are also available.

Non-stick properties

Special coatings enable handling of sticky and adherent materials. For example, Sheet-Mould-Compound (SMC) and other sticky fiber matrix semi-finished products can be handled without residue.

Needle grippers suitable for your solution are also included PTFE-coated contact surfaces and/or needles are used to enable residue-free gripping. The difference is particularly clear in the case of renewable natural fibers with a compound admixture that adheres when heated, but not on our non-stick coated needle grippers.

Solution-oriented products

We will find solutions for you and your handling tasks - regardless of whether they are prototypes or series production. Based on our needle grippers in the construction kit catalogue, we adapt the needle gripper to suit your projects.

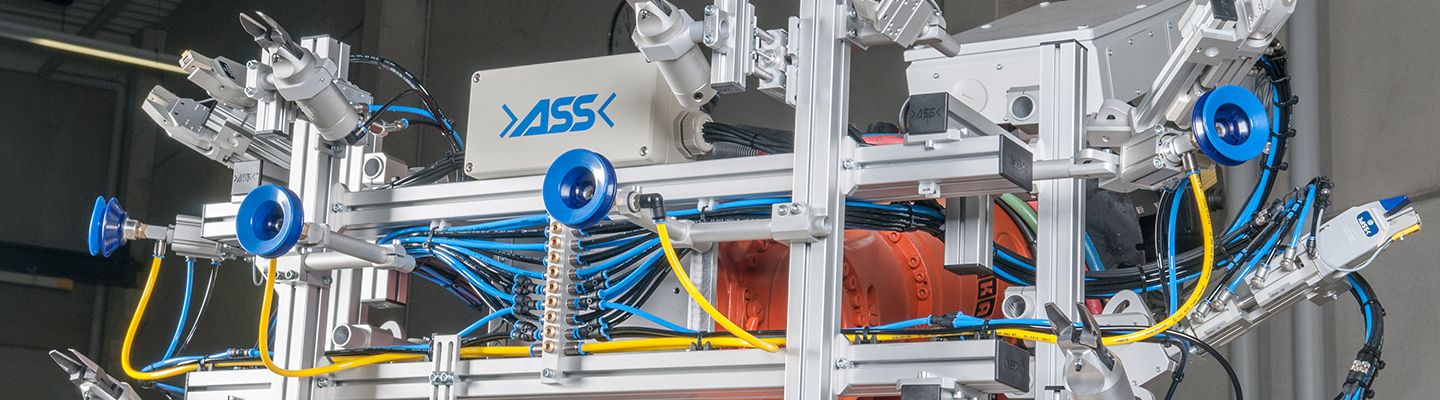

Easy connection

Our modular system contains numerous cross-system connections to enable you to integrate the needle grippers in an economical and simple way. For example, our robot hand kit also includes spring-loaded connections as a standard component.

Testing and field trials

In the case of limp or adhesive materials, material tests are particularly in demand. We would be happy to advise you on site or carry out tests at our site in Overath.

The difference in renewable natural fibers with a compound admixture, which adheres when heated, is particularly evident on the non-stick coated needle grippers no natural fibers stick.

Quality and ability to deliver

ASS components are technically high quality, durable and always an economical solution. We develop, design and produce our components at the certified climate-neutral location in Overath. Your CO2 footprint also benefits from the emission reduction in Scope 3. Our high level of vertical integration enables us to react quickly to your requests. We are at your disposal as a contact person for solving your tasks for a non-binding consultation. You can reach us by telephone on +49 (0)2206/90547-0 or by e-mail at

More solutions

You can find a comprehensive overview of all mechatronic components of the construction kit with the most important key data such as prices, drawings and dimensions as well as operating instructions for our articles in our online catalogue.