Automation systems take over complex work processes

The requirements in production for highly automated manufacturing processes with short set-up and maintenance times are increasing. With our automation systems, we enable our customers to increase production efficiency and process reliability while simultaneously saving costs and achieve a high processing quality guarantee.

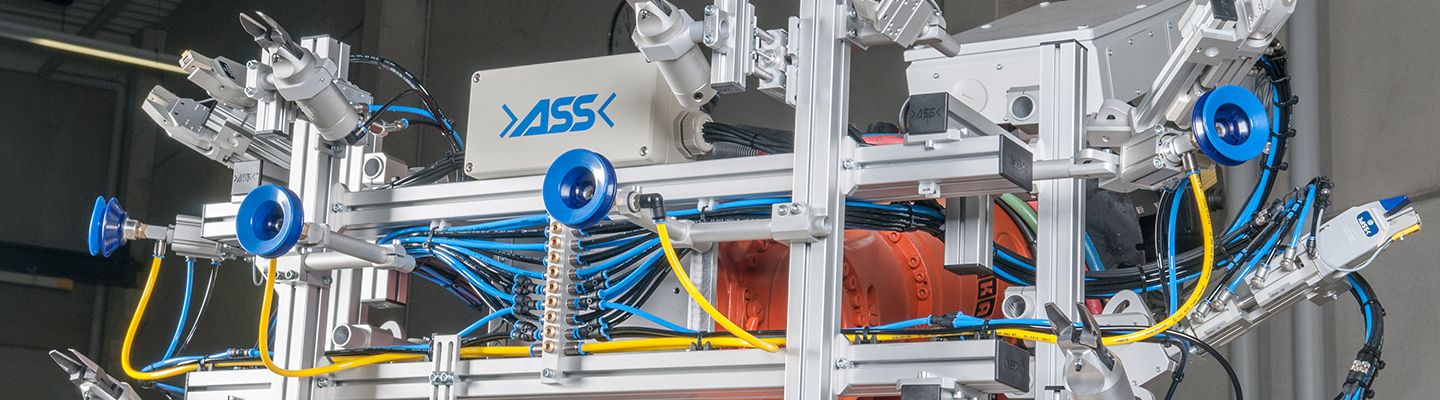

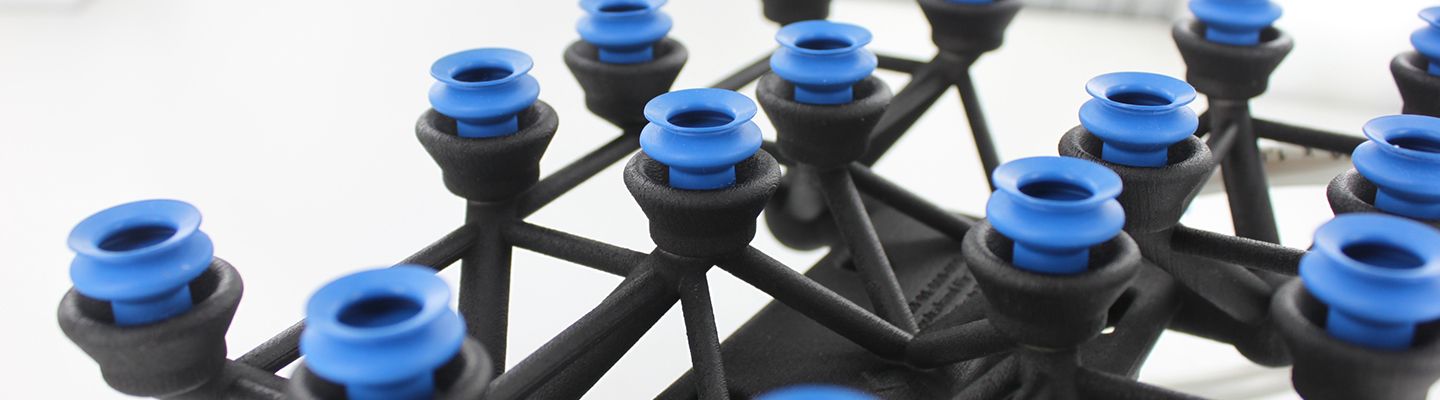

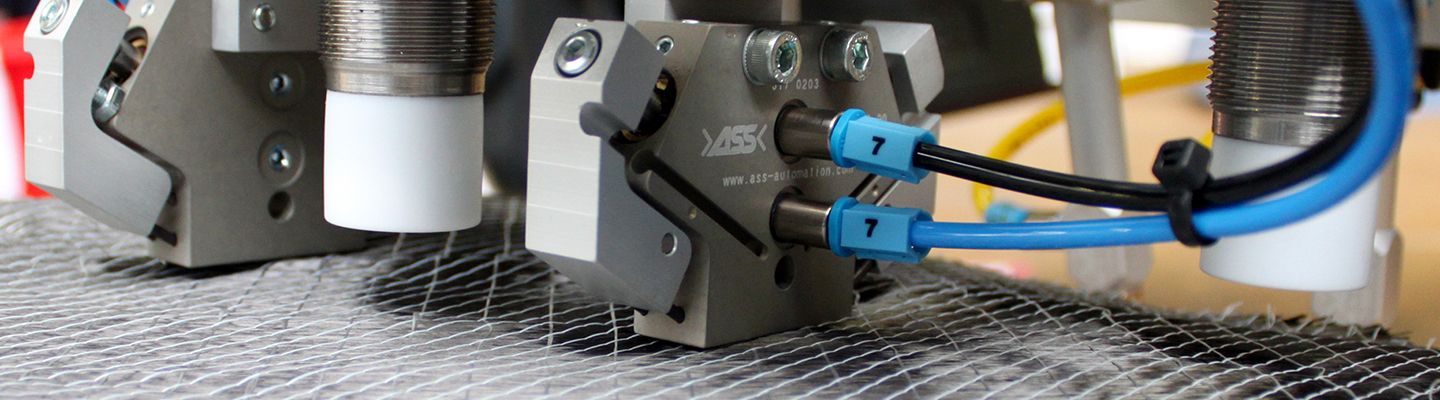

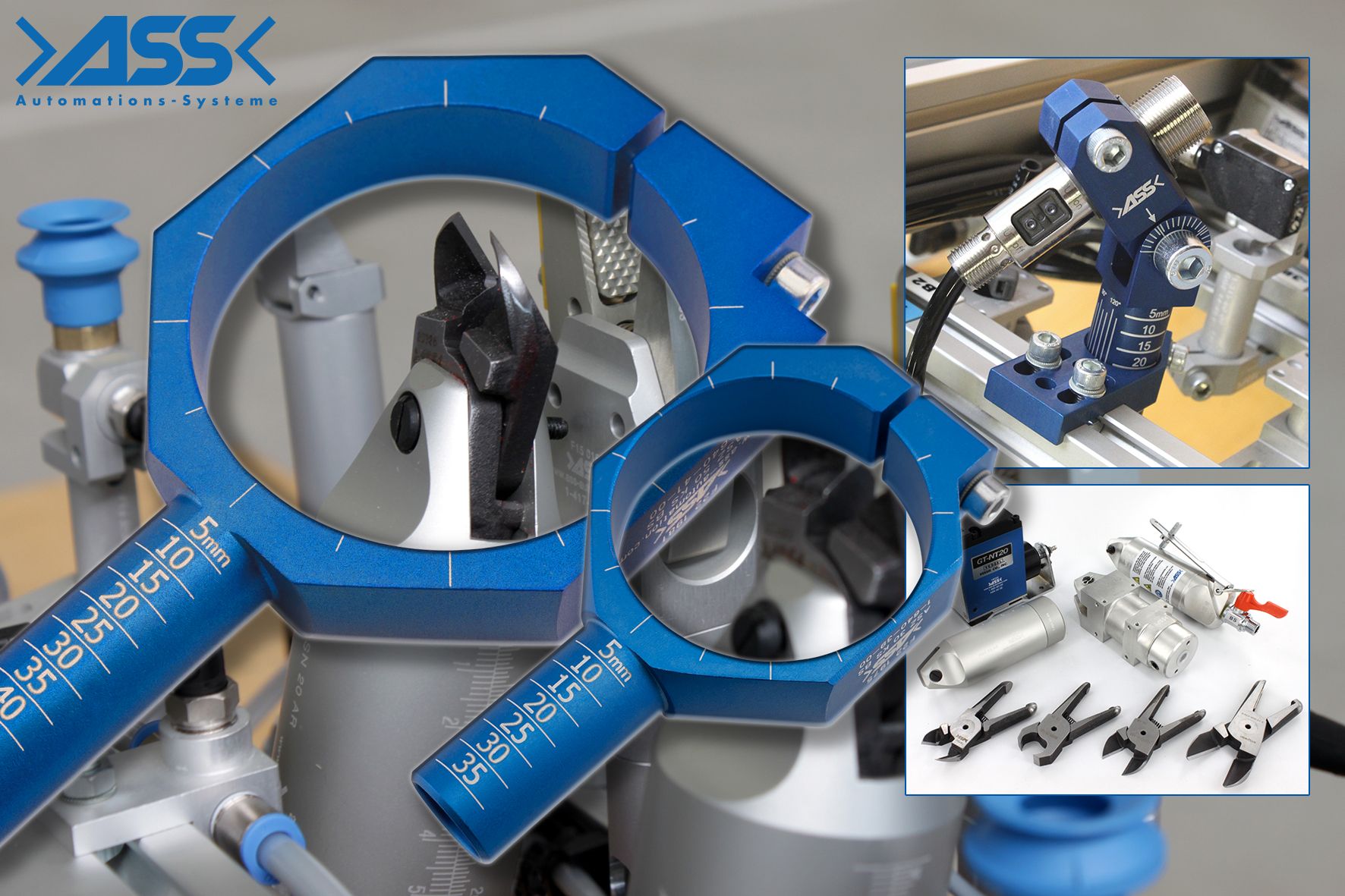

Our tailor-made automation systems also include the programming and integration of robot systems. We have specialized in automation in plastic injection molding production. For example, gripping, conveying, testing and feeding technology as well as robots and assembly technology are combined in such a way that a tailor-made and application-oriented solution can be found for every customer.

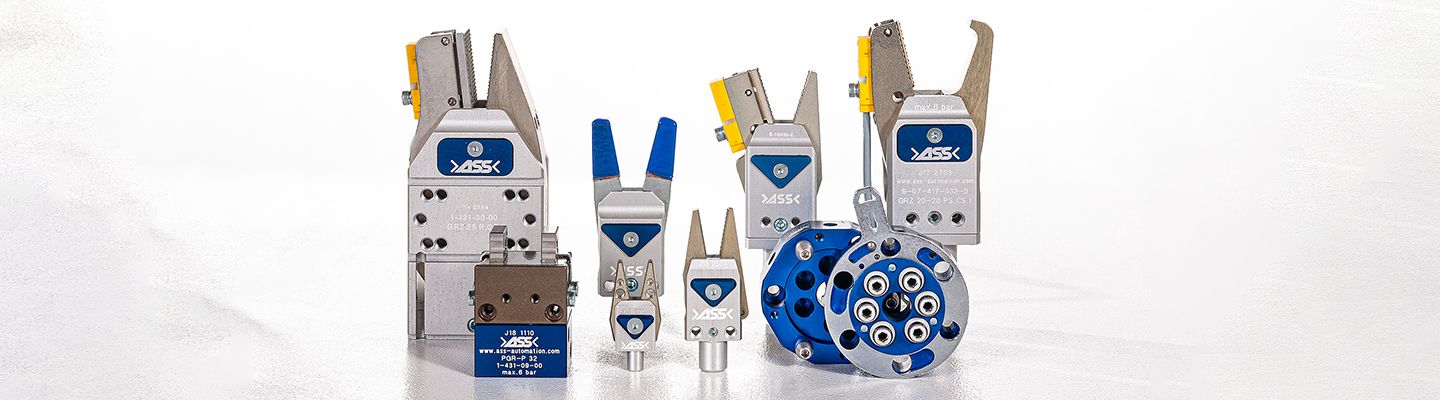

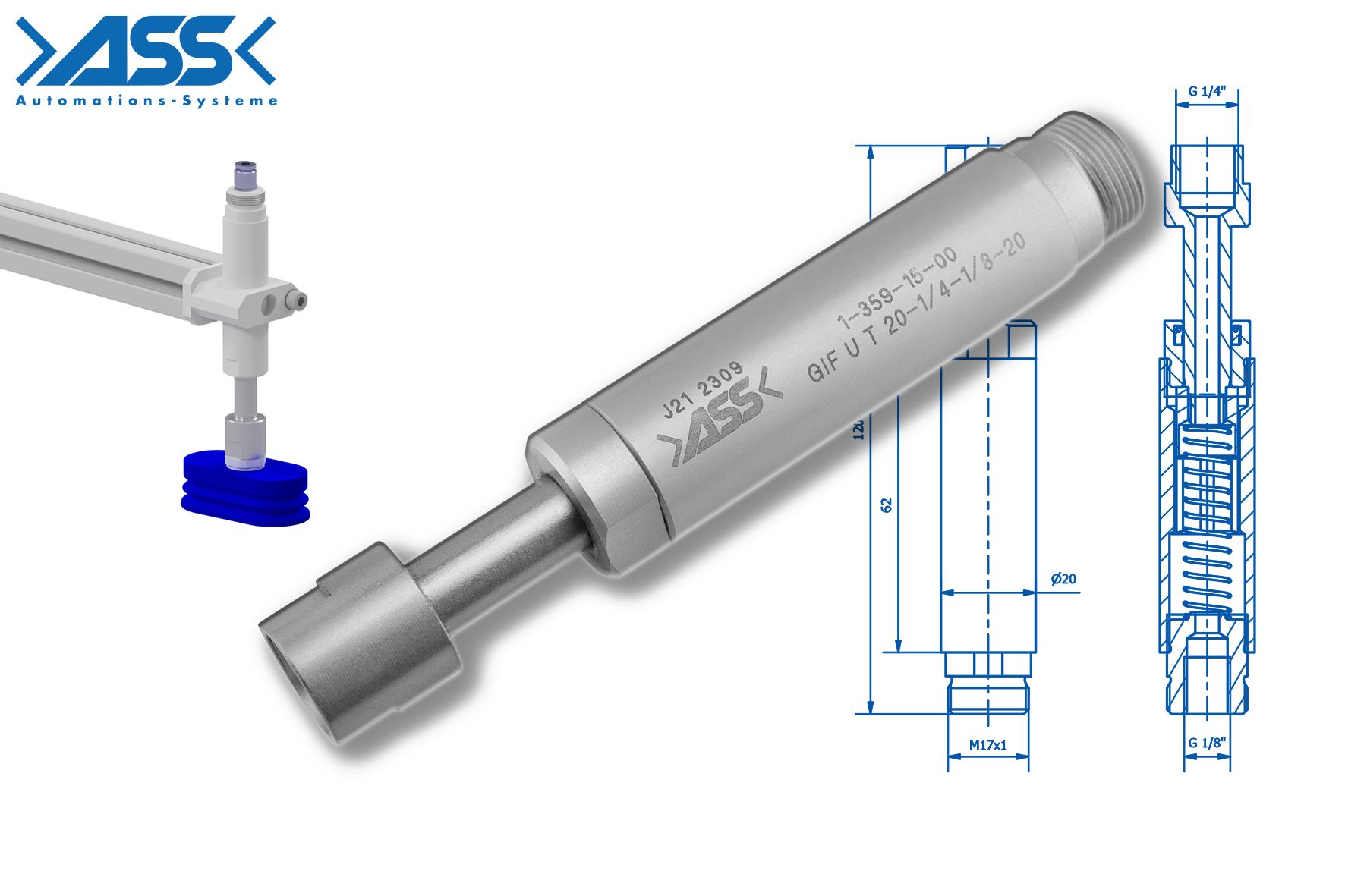

With our mechatronic gripping components, we offer Solutions tried and tested in practice. A lot is possible for maximum performance in the areas of e-mobility. Our automation systems and processing centers are used, among other things, in the production of individual battery cells to battery packs, from electrical plugs to charging stations or the smallest Plastic parts to high-gloss interior components or large exterior components, such as bumpers.

Everything from a single source

From construction to programming and assembly, to maintenance, we can do the entire process for you from a single source offer. Of course, technical documentation for your systems will also be created by our qualified employees in accordance with the valid Machinery Directive.

Quality is one of the most important arguments for us and our customers. It goes without saying that we also supply the declaration of conformity for automation systems in accordance with the EC Machinery Directive. Our quality management has been certified according to ISO 9001 for many years and we have been a certified climate-neutral location since 2021.